When we think about the things we utilize everyday-- cars and trucks, kitchen devices, electronic devices, and also the little components inside our gizmos-- it's simple to neglect the procedures that make them feasible. One of the unhonored heroes of modern production is metal stamping, an effective technique that forms metal into specific, useful parts. Though it's typically hidden behind the scenes, this approach plays a central function in making our lives extra effective, comfortable, and attached.

Recognizing the Art Behind Metal Stamping

At its core, metal stamping is the procedure of changing level steel sheets right into certain shapes with force and accuracy. This isn't a one-size-fits-all operation; it includes numerous techniques like bending, punching, creating, and embossing-- each selected for the job at hand. Every bend and cut is executed with unbelievable precision, assisted by the devices and dies crafted for the job.

This process requires greater than just makers-- it requires an experienced team and advanced technology. The creativity of tool and die shops depend on developing customized dies that permit the specific recreation of components, to the smallest detail. Whether creating easy brackets or intricate auto elements, precision is non-negotiable.

Just How Metal Stamping Powers Modern Living

Take a look around your office or home and you'll find many items gave birth to by metal stamping. The architectural structure of your dish washer, the adapters in your smart device, the brace holding your automobile's dashboard-- all these parts owe their existence to stamped metal.

In the automotive world, the demand for resilience and uniformity makes progressive die stamping a favored. This strategy involves a collection of terminals, each executing an unique function as the steel developments via journalism. It's excellent for high-volume runs and makes certain each item satisfies exacting standards.

Yet it does not stop with automobiles. In the medical field, where dependability can be a matter of necessity, metal stamping is made use of to craft medical devices and gadget elements. In the aerospace sector, marked parts must stand up to extreme conditions while satisfying tight tolerances. The exact same holds true in consumer electronics, where space-saving, high-functionality designs call for stamped metal elements that are both light-weight and solid.

Precision, Speed, and Reliability: Why Metal Stamping Matters

So why has metal stamping end up being such a go-to method throughout numerous sectors? Most importantly: rate. Once the passes away are set up, thousands of the same components can be created with little variation. This degree of repeatability is crucial when consistency matters.

After that there's the concern of cost-effectiveness. Traditional machining might take longer and entail more material waste. Yet marking, particularly when finished with progressive die innovation, keeps manufacturing scooting and efficiently. It's one of the most intelligent means to satisfy high-volume manufacturing objectives without compromising quality.

The integrity of this process additionally can not be overstated. When you're generating thousands-- and even millions-- of components, a little flaw can come to be a huge trouble. That's why partnering with a knowledgeable tool and die company is so vital. The right group guarantees every component is made to spec, whenever.

Inside the World of Tool and Die: What Makes the Magic Happen

Behind every terrific stamped item is a team of specialists crafting and keeping the devices and passes away that make production feasible. In numerous means, tool and die shops are the heart of the operation. They create the dies, fix any kind of manufacturing issues, and make certain the stamping process runs smoothly throughout.

This level of craftsmanship isn't accomplished over night. It takes years of hands-on experience, training, and a deep understanding of products and machinery. These experts are problem-solvers and trendsetters, continuously fine-tuning their approaches to boost rate, minimize waste, and increase item quality.

While automation has made terrific strides, there's still no replacement for the understanding and adaptability of human experts. From dealing with CAD software application to improving a model, the job performed in tool and die shops merges modern technology with typical precision engineering.

Developing With Industry Demands

As markets continue to develop, so too does metal stamping. Makers are exploring brand-new alloys, tighter resistances, and a lot more small styles. With these changes come new obstacles-- and possibilities.

For instance, as electric vehicles (EVs) gain appeal, there's a growing need for lightweight elements that can hold up against high performance and severe temperature levels. Stamping fulfills these needs, offering solid yet effective parts without including mass.

Smart home tools and wearables additionally rely on stamped steel components to maintain their profiles streamlined while securing sensitive inner elements. The surge great post of miniaturization is pushing the borders of what metal stamping can do, and the very best tool and die company will constantly be ready to introduce alongside sector patterns.

The Future Is Stamped

What's most exciting is exactly how this technology remains to push the envelope. With innovative materials, automation, and information analytics, the future of metal stamping looks also brighter. These tools will certainly help suppliers respond faster to market modifications, increase sustainability, and continue boosting performance and style.

Yet, also as the market advances, one truth continues to be: quality matters. It's the dedication to quality from competent specialists in tool and die shops that guarantees each stamped item executes exactly as it should, whether it's powering your morning coffee maker or a satellite in orbit.

Keep Connected to the Process That Shapes Your World

From the smallest electronic port to the structure of your car, metal stamping is anywhere. And as modern technology advances, this vital production procedure just expands in importance and possibility. Curious about how the everyday products around you are made? Or how development is driving smarter, a lot more effective production? Follow our blog to stay in the loop.

We're just starting-- ensure to inspect back typically for more behind-the-scenes stories, sector understandings, and updates on just how progressive die, tool and die shops, and specialist tool and die company groups are shaping the world, one stamped component at once.

Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Jaclyn Smith Then & Now!

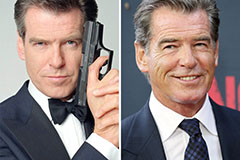

Jaclyn Smith Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!